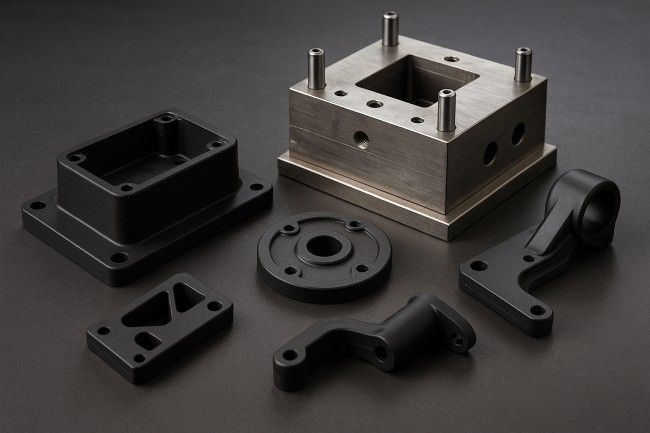

Custom Molded Components Built for Performance

In industries where precision and durability are non-negotiable, off-the-shelf parts often fall short. Custom molded components offer a tailored solution, designed to meet the exact specifications of demanding applications. This post explores the advantages of custom molding and how it delivers superior performance, reliability, and value across various sectors.

The demand for high-performance parts is growing across industries like aerospace, medical technology, and automotive manufacturing. Standard components can introduce inefficiencies, compromises in design, and potential points of failure. Custom molding addresses these challenges by creating parts that are perfectly aligned with a product’s functional requirements. By optimizing material selection, design, and manufacturing processes, businesses can achieve enhanced performance that commodity parts simply cannot match. We’ll explore how this tailored approach leads to better products and a stronger competitive edge.

Why Choose Custom Molding?

Opting for custom molded components over standard parts provides a strategic advantage. It allows for complete control over every aspect of the component’s design and production, ensuring it integrates seamlessly into the final product and performs flawlessly under specific operating conditions.

Precision and Perfect Fit

One of the primary benefits of custom molding is the ability to achieve unparalleled precision. Standard parts are made to general specifications, which can lead to slight inconsistencies or the need for modifications during assembly. Custom components are engineered to fit perfectly, eliminating gaps, reducing assembly time, and minimizing the risk of mechanical stress or failure. This exact fit is crucial in complex systems where every micron counts.

Material Optimization for Peak Performance

Not all applications are the same, and neither are their material requirements. Custom molding allows you to select the ideal polymer or composite for your specific needs. Do you need a component that can withstand extreme temperatures, resist harsh chemicals, or offer exceptional strength-to-weight ratios? With custom molding, you can choose from a vast library of advanced materials to ensure your component has the right properties for its environment. This material specificity is vital for parts used in critical applications, such as a durable filter plate in a processing system, where standard materials might degrade or fail.

Enhanced Design Freedom and Functionality

Custom molding liberates engineers from the constraints of standard part geometries. This freedom allows for the creation of complex, multi-functional components that can consolidate several parts into a single unit. Integrating features like brackets, hinges, or channels into one molded piece reduces part count, simplifies assembly, and lowers overall production costs. It also opens the door to innovative designs that can improve a product’s efficiency, reduce its weight, and enhance its aesthetic appeal.

The Custom Molding Process: A Path to Quality

Achieving high-performance custom components involves a meticulous, multi-stage process that ensures quality from concept to production. Each step is critical for translating a design into a reliable and effective final product.

Collaboration and Design

The process begins with a close collaboration between the client and the molding experts. During this phase, engineers work to understand the application’s requirements, including functional needs, environmental conditions, and performance expectations. Using advanced CAD software, a detailed 3D model of the component is created and refined. Simulation tools like Finite Element Analysis (FEA) are often used to predict how the part will behave under stress, ensuring the design is robust before any physical tooling is made.

Tooling and Prototyping

Once the design is finalized, a precision mold, or tool, is manufactured. This is a critical investment, as the quality of the mold directly impacts the quality of the final parts. Before committing to full-scale production, prototypes are often created using methods like 3D printing or a preliminary mold. Prototyping allows for physical testing and validation of the design, ensuring it meets all specifications. Any necessary adjustments can be made at this stage, saving time and resources down the line.

Production and Quality Assurance

With a proven design and a high-quality mold, the production phase begins. The chosen material is injected into the mold under precise temperature and pressure conditions. Throughout the production run, rigorous quality control measures are in place. Automated inspection systems and manual checks ensure that every component meets the required dimensional tolerances and material standards. This commitment to quality guarantees that each part delivered is consistent, reliable, and ready for integration.

Elevate Your Products with Custom Solutions

Custom molded components are more than just parts; they are engineered solutions that drive performance and innovation. By moving beyond the limitations of standard components, businesses can create products that are more reliable, efficient, and competitive. The investment in custom molding pays dividends through improved product quality, reduced assembly costs, and enhanced brand reputation. If your goal is to build products that are truly built for performance, embracing a custom approach is the definitive path forward.