Quality Harness Production for Technical Applications

Wire harnesses serve as the nervous system of modern technical equipment, connecting critical components across industries from aerospace to medical devices. When these intricate assemblies fail, entire systems can shut down, leading to costly downtime and potential safety hazards.

Understanding what separates high-quality harness production from standard manufacturing can mean the difference between reliable performance and catastrophic failure. Technical applications demand precision, durability, and strict adherence to specifications that go far beyond basic electrical connections.

The stakes are particularly high when you consider that a single faulty connection in an aircraft control system or medical monitoring device could have life-threatening consequences. This reality drives the need for exceptional manufacturing standards and quality control processes.

Core Elements of Superior Harness Manufacturing

Material Selection and Specification

The foundation of any quality wire harness begins with selecting appropriate materials for the specific application environment. Temperature extremes, chemical exposure, vibration, and electromagnetic interference all influence material choices.

High-grade copper conductors provide optimal electrical performance, while specialized insulation materials protect against environmental hazards. For aerospace applications, flame-retardant materials meeting strict flammability standards are essential. Medical device harnesses require biocompatible materials that won’t degrade when exposed to sterilization processes.

Cable shielding becomes critical in environments with electromagnetic interference. Proper shield termination and grounding techniques ensure signal integrity remains intact throughout the harness lifecycle.

Precision Assembly Techniques

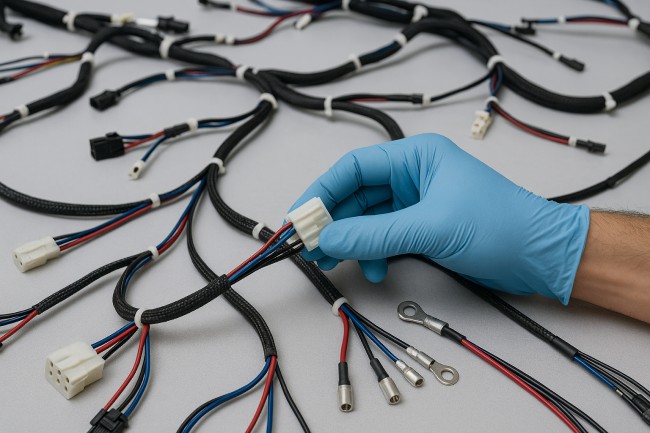

Quality harness production relies heavily on skilled craftsmanship combined with advanced manufacturing equipment. Automated crimping machines ensure consistent connection quality, while manual assembly allows for complex routing and positioning requirements.

Proper wire management includes maintaining appropriate bend radii to prevent conductor damage and ensuring adequate strain relief at connection points. Service loops built into the harness design accommodate installation variations and potential repairs.

Color coding and labeling systems help technicians during installation and maintenance procedures. Clear identification reduces the risk of incorrect connections that could damage expensive equipment.

Quality Control and Testing Protocols

Electrical Testing Standards

Comprehensive electrical testing forms the backbone of quality assurance in harness production. Continuity testing verifies that all intended connections are properly made, while insulation resistance testing confirms that unwanted current paths don’t exist.

High-voltage testing, often called hipot testing, applies voltages well above normal operating levels to identify potential insulation failures before they occur in service. This destructive testing method helps predict long-term reliability.

For high-frequency applications, impedance testing ensures signal integrity across the entire harness. Crosstalk measurements verify that adjacent conductors don’t interfere with each other during normal operation.

Physical Inspection Procedures

Visual inspection remains an irreplaceable component of quality control. Trained inspectors examine crimp quality, insulation integrity, and overall workmanship using magnification equipment when necessary.

Pull testing validates the mechanical strength of connections, ensuring they can withstand installation stresses and operational loads. Bend testing confirms that the harness maintains electrical continuity through repeated flexing cycles.

Documentation of all test results provides traceability and helps identify trends that might indicate process improvements or material issues.

Industry-Specific Requirements

Aerospace and Defense Applications

Military and aerospace harnesses must meet stringent standards including MIL-SPEC requirements and AS9100 quality management systems. These applications often involve extreme temperature ranges, high vibration environments, and exposure to various chemicals and fluids.

Traceability requirements mean that every component can be tracked back to its original source, including wire lot numbers, connector batch codes, and assembly personnel records. This level of documentation supports failure analysis and reliability assessments.

Medical Device Integration

Medical device harnesses face unique challenges including biocompatibility requirements and sterilization compatibility. FDA regulations add another layer of quality requirements that must be carefully managed throughout production.

Clean room assembly may be necessary for implantable device harnesses, while others must withstand repeated autoclaving without degradation. Custom wire harness manufacturers specializing in medical applications understand these specialized requirements.

Industrial Automation Systems

Factory automation harnesses must operate reliably in harsh industrial environments with temperature cycling, chemical exposure, and mechanical stress. EMI shielding becomes critical when harnesses run alongside high-power motor controllers and switching equipment.

Flexible harnesses for robotic applications require special consideration for fatigue life, as they may undergo millions of flex cycles during normal operation.

Advancing Manufacturing Excellence

The evolution of harness production continues with advances in materials science and manufacturing technology. Automated testing equipment provides faster, more comprehensive quality assessment while reducing human error.

Design software integration allows for better optimization of wire routing and connector placement, reducing assembly time and improving reliability. 3D modeling helps identify potential issues before physical prototypes are built.

Continuous improvement programs help manufacturers stay ahead of evolving industry requirements and customer expectations. Regular training ensures that assembly personnel maintain the skills necessary for producing high-quality harnesses.

Building Reliable Connections for Critical Applications

Quality harness production requires a comprehensive approach that addresses material selection, manufacturing processes, and rigorous testing protocols. The investment in proper procedures and equipment pays dividends through improved reliability and reduced field failures.

Organizations requiring technical wire harnesses should partner with manufacturers who demonstrate expertise in their specific industry requirements. Look for certifications relevant to your application and ask for documentation of quality processes and testing capabilities.

The complexity of modern technical systems continues to increase, making the role of quality harness production even more critical to overall system success.